Corn germ oil production line manufactured by Henan Huatai Cereals and Oils Machinery Co., Ltd. has 1V1 guidance to customers and provides you with a full automatic control turnkey project with 10-2000TPD Capacity.

Huatai corn germ oil production line adopts low-temperature pressing or gentle corn oil extraction process to completely retain the vitamin E and unsaturated fatty acids in corn oil. The unique corn oil dewaxing process makes the oil clearer and does not become turbid even after long-term storage. The corn germ oil production line has a high degree of automation, and it is completed in one go from raw materials to finished products, ensuring that every drop of oil is pure and mellow.

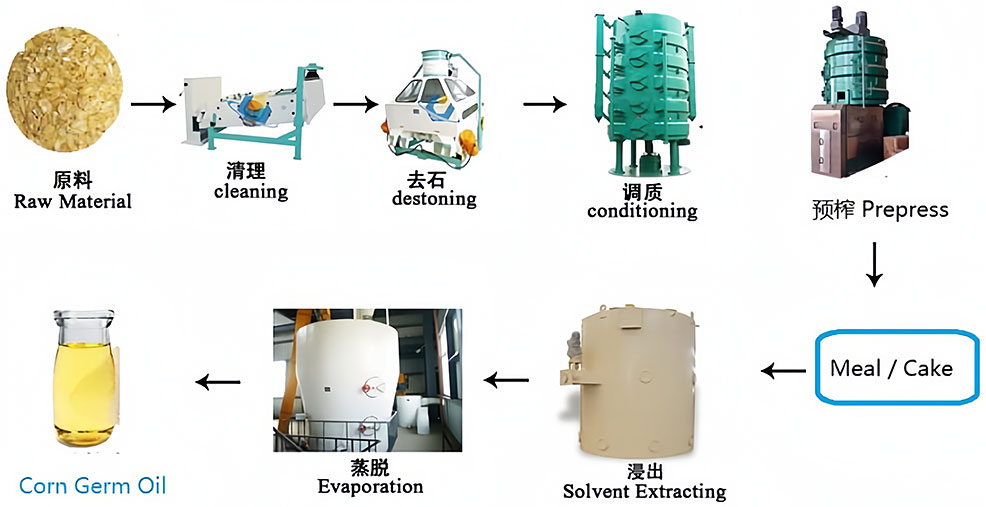

Corn germ oil is extracted from corn germ, which is one of the most commonly used cooking oil. A complete corn germ oil production line includes corn germ pretreatment and prepressing machine, corn germ cake solvent extraction plant and crude corn germ oil refinery plant.

1. Corn Germ Oil Pretreatment and Prepressing Plant:

1. Corn Germ Oil Pretreatment and Prepressing Plant:

Corn germ → cleaning → softening → flaking → cooking → prepressing→ crude corn germ oil + corn germ cake

Major Equipment: Vibrating screen, magnetic separator, softening equipment, flaking roll, vertical cooker, screw oil press.

Cleaning

Cleaning

The corn germ extracted contains starch which can affect the oil yield and oil quality. Corn germ pretreatment and prepressing plant adopts vibration screen to remove the starch and bran in the corn germ to improve the purity. Adopts magnetic separator to remove the metal impurities to protect the equipment.

Softening

Softening

The cleaned corn germ enters the softening equipment to adjust the moisture content and temperature to increase the plasticity.

Flaking

Flaking

The softened corn germ enters the flaking roll in the corn germ pretreatment and prepressing plant to be made into 0.3-0.4 mm flakes. Flaking is to destroy the cell wall, which is good for oil yielding.

Cooking

Cooking

The corn germ flakes enter the vertical cooker for the cooking process. Cooking can denature the protein and make it solidify, agglutinate the oil and reduce the viscosity, which is good for oil pressing.

Prepressing

Prepressing

The cooked corn germ flakes enter the screw oil press which integrates adjusting cooker to adjust the moisture content and temperature of the cooked materials. The crude oil is filtered to remove the impurities and then enters the refining workshop. The pre-pressed cake is sent to the corn germ oil solvent extraction workshop for oil extraction.

2. Corn Germ Cake Solvent Extraction Plant:

2. Corn Germ Cake Solvent Extraction Plant:

Corn germ cake solvent extraction plant uses the organic solvent to extract oil from the corn germ cake through soaking or spraying methods. There is only less 1% oil content in the meal after solvent extraction. This section includes corn germ oil extraction, wet meal desolventizing, miscella evaporation and stripping, solvent condensation and vent gas recovery.

Major Equipment: Oil extractor, D.T.D.C desolventizer-toaster, evaporator, stripping tower, condenser, recovery system

The corn germ cake from the prepressing plant enters the oil extractor, where the solvent is used to extract oil from the cake. The wet meal discharged from the oil extractor is sent into the desolventizer to remove the solvent. The dried meal obtained is sent to the meal warehouse for packaging. The mixed vapor discharged from the desolventizer enters the shell pass of the first evaporator as the heat source.

The corn germ cake from the prepressing plant enters the oil extractor, where the solvent is used to extract oil from the cake. The wet meal discharged from the oil extractor is sent into the desolventizer to remove the solvent. The dried meal obtained is sent to the meal warehouse for packaging. The mixed vapor discharged from the desolventizer enters the shell pass of the first evaporator as the heat source.

The miscella from the oil extractor is pumped into the first evaporator, the second evaporator and the disk stripping tower in the corn oil extraction plant to remove the solvent. The crude extracted oil obtained enters the refining workshop.

The miscella from the oil extractor is pumped into the first evaporator, the second evaporator and the disk stripping tower in the corn oil extraction plant to remove the solvent. The crude extracted oil obtained enters the refining workshop.

The solvent vapor in the corn oil plant enters the condenser. The condensate enters the water separator. The solvent separated enters the solvent holding tank. The water separated is boiled to recover the solvent.

The solvent vapor in the corn oil plant enters the condenser. The condensate enters the water separator. The solvent separated enters the solvent holding tank. The water separated is boiled to recover the solvent.

The vent gas in the extraction plant enters the last condenser. The vent gas from the last condenser enters the mineral oil system in the corn oil solvent extraction plant to recycle the solvent.

The vent gas in the extraction plant enters the last condenser. The vent gas from the last condenser enters the mineral oil system in the corn oil solvent extraction plant to recycle the solvent.

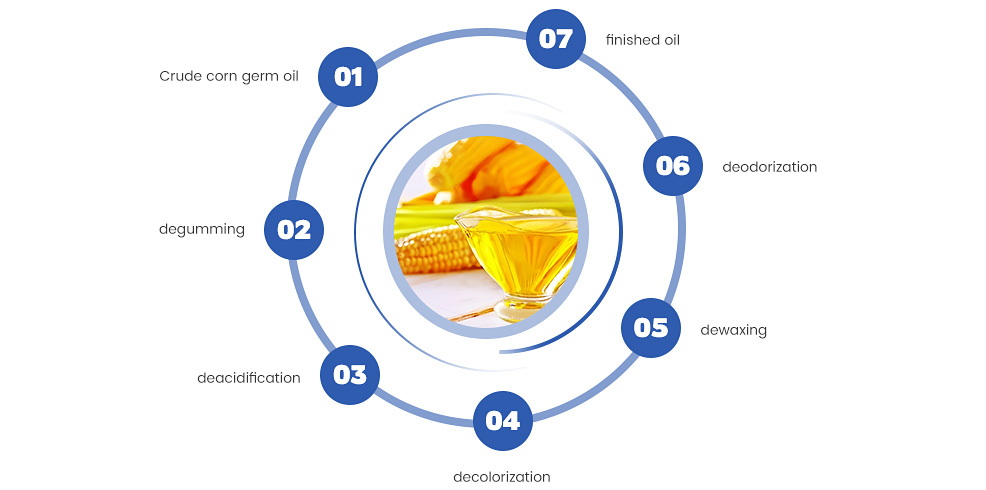

3. Corn Germ Oil Refinery Plant:

3. Corn Germ Oil Refinery Plant:

Corn oil refinery plant is to remove the unneeded and hazardous substances such as phospholipids, free fatty acids, wax, pigment and unpleasant smell in the crude corn germ oil to obtain qualified refined oil;

The process of corn germ oil refinery plant: Crude corn germ oil→degumming→deacidification→decolorization→dewaxing→deodorization→finished oil

Major Equipment: Degumming tank, nentralizing tank, decolorizing tank, crystalizer, deodorization tower, centrifuge, filter, vacuum pump, heat conducting oil furnace.

The filtered crude corn germ oil is preheated and mixed with phosphoric acid in the corn oil refinery. The colloids such as phospholipids absorb water and expand to form the emicelle which are precipitated to be removed.

The filtered crude corn germ oil is preheated and mixed with phosphoric acid in the corn oil refinery. The colloids such as phospholipids absorb water and expand to form the emicelle which are precipitated to be removed.

The degummed oil enters the alkali refining tank and alkali liquid is added which reacts with free fatty acid to form soapstocks. The soapstocks are precipitated to be removed. Part of the impurities like pigment, phospholipids, protein and mucus are also adsorbed on the soapstocks to be removed.

The degummed oil enters the alkali refining tank and alkali liquid is added which reacts with free fatty acid to form soapstocks. The soapstocks are precipitated to be removed. Part of the impurities like pigment, phospholipids, protein and mucus are also adsorbed on the soapstocks to be removed.

The neutral oil is heated and soft water is added for water washing. Then the oil is centrifuged to remove the wastewater.

The neutral oil is heated and soft water is added for water washing. Then the oil is centrifuged to remove the wastewater.

The water washed oil enters the decolorizing tank and is heated and dried under vacuum. The oil is then fully mixed with bleaching clay. After bleaching, the mixture is filtered to remove the waste clay. The decolorized oil enters the crystalizer in the corn germ oil production line and filter aid is added. Then the oil is cooled rapidly for crystallization. The mixture is filtered to remove the wax.

The water washed oil enters the decolorizing tank and is heated and dried under vacuum. The oil is then fully mixed with bleaching clay. After bleaching, the mixture is filtered to remove the waste clay. The decolorized oil enters the crystalizer in the corn germ oil production line and filter aid is added. Then the oil is cooled rapidly for crystallization. The mixture is filtered to remove the wax.

The dewaxed oil enters the deaerator to remove the air and then enters the deodorization tower for deodorization. The deodorized oil is filtered to obtain the refined corn germ oil.

The dewaxed oil enters the deaerator to remove the air and then enters the deodorization tower for deodorization. The deodorized oil is filtered to obtain the refined corn germ oil.

4. Company Strength and Advantages

4. Company Strength and Advantages

Henan Huatai Cereals and Oils Machinery Co., Ltd. was established in 1988. It is a national high-tech enterprise with many patented technologies in the field of corn germ oil processing. The company's production base covers an area of 100,000 square meters and is equipped with large CNC machining centers, automated welding equipment and testing laboratories. The company has established a complete after-sales service system, with multiple agency centers and service outlets in major markets around the world, providing free technical consultation, and has been exported to Southeast Asia, Africa, South America and other regions.

As one of the top grain and oil machinery manufacturer and supplier, with many provincial honors and the experience in building hundreds of corn oil mills, Henan Huatai Cereals and Oils Machinery Co., Ltd. has outstanding strength in the field of corn oil production line, focusing on corn oil technology innovation and process improvement for many years.

With rich industry experience, we provide customers with a full range of solutions from corn cleaning processing to corn oil refining and packaging. For different corn oil production processes, we can provide customized 10-2000TPD corn germ oil production lines, support a variety of capacity tonnage and process combinations, to meet the diverse needs of customers.

5. After-sales and Maintenance Services

5. After-sales and Maintenance Services

Henan Huatai Cereals and Oils Machinery Co., Ltd., as one of the professional oil and fat equipment manufacturer, usually provides after-sales and maintenance services for corn oil processing equipment in the following aspects (subject to the company's latest policy):

Equipment installation and commissioning

Equipment installation and commissioning

1) On-site guidance: Send engineers to the customer's corn oil factory to provide guidance on the installation of corn oil equipment to ensure that the equipment is properly in place.

2) Commissioning service: Assist in completing corn oil equipment no-load and load commissioning and optimize corn oil production process parameters.

3) Operation training: Provide equipment operation, maintenance and safety specification training for customer technicians.

Warranty and maintenance

Warranty and maintenance

1) Warranty period: Provide a warranty period of 1-3 years (depending on the terms of the contract), and handle problems caused by equipment quality free of charge during the warranty period.

2) Fault response: Set up a 48-hour service hotline to quickly respond to fault reports and quickly send engineers to the site for inspection and repair when necessary.

3) Accessories supply: Provide original accessories at a preferential price to ensure long-term and stable operation of the corn oil machine.

Technical support and upgrade

Technical support and upgrade

1) Process optimization: Adjust equipment parameters according to customer needs to improve oil yield and energy efficiency.

2) Technical consultation: Provide free technical consultation for life to answer difficult problems in production.

3) Equipment upgrade: Provide corn oil plant upgrade and technology iteration solutions (such as control system upgrade, energy-saving transformation, etc.).

6. How to Set Up a Corn Oil Processing Plant?

6. How to Set Up a Corn Oil Processing Plant?

To build a corn oil production line, many aspects need to be considered.

Huatai Oil Machinery has extensive experience in building turnkey project corn oil production line and overseas export of corn oil processing equipment. To buy our corn oil equipment, just provide the following information and we will arrange an experienced foreign trade sales manager to talk with you:

Corn oil equipment parameters and list:

1) What capacity of corn oil production machine do you need? How many tons do you deal with corn germ every day? Or how much crude corn oil do you want?

2) Do you just process corn germ or multiple oilseeds? Do you need a single equipment, an entire workshop, or the complete set of corn oil turnkey projects?

3) What corn germ oil process do you need? Pressing, solvent extraction, refining equipment or others?

4) Do you have a certain amount of budget and land that meets the conditions for building a corn oil factory?

5) Other export trade needs, such as contract signing details, payment methods, logistics and installation and construction, etc.

Please leave us a message as detailed inquiry information as possible, so that we can provide you with equipment quotation, process flow, equipment configuration list and other services, thank you.