Soybean oil is one of the most consumed vegetable oils in the world and is widely used in cooking, food processing and industrial production. So how does soybean oil turn from soybeans into clear edible oil? As one of the leading companies in the grain and oil machinery industry, Henan Huatai Cereals and Oils Machinery Co., Ltd. will give you a detailed introduction to the soybean oil processing technology and key technologies of soybean oil.

1. The main process of soybean oil processing

Soybean oil processing mainly includes pretreatment, pressing or extraction, refining and other steps, each of which directly affects the quality and yield of the oil.

1) Soybean pretreatment

Pretreatment is the first step in soybean oil processing, mainly including:

Cleaning and removing impurities: remove impurities in soybeans, such as stones, metals, straw, etc., to ensure the purity of the raw materials.

Crushing and peeling: soybeans are crushed by a crusher and the bean skins are separated to reduce the impurity content in the oil.

Softening and rolling: by adjusting the moisture and temperature of soybeans, they are softened and rolled into thin sheets for subsequent oil extraction.

2) Oil extraction (pressing or extraction)

There are two main methods for extracting soybean oil: mechanical pressing and solvent extraction.

Mechanical pressing: Using a screw oil press to physically press soybean flakes, it is suitable for small-scale production. The oil is natural but the residual oil rate is high.

Solvent extraction: Using solvents such as n-hexane to dissolve oil, it has high extraction efficiency and low residual oil rate. It is the current mainstream soybean oil extraction method.

3) Crude oil refining

The freshly extracted crude soybean oil contains impurities such as phospholipids, free fatty acids, and pigments. It needs to be refined before it can be eaten. The main steps of soybean oil refinery plant include:

Degumming: Remove phospholipids and colloids to prevent oil rancidity.

Deacidification: Neutralize free fatty acids through alkali refining to improve oil stability.

Decolorization: Use activated white clay to adsorb pigments to make the oil clearer.

Deodorization: High-temperature vacuum distillation removes odors and improves the flavor of edible oil.

2. Advanced Technology of Henan Huatai Cereals and Oils Machinery Co., Ltd.

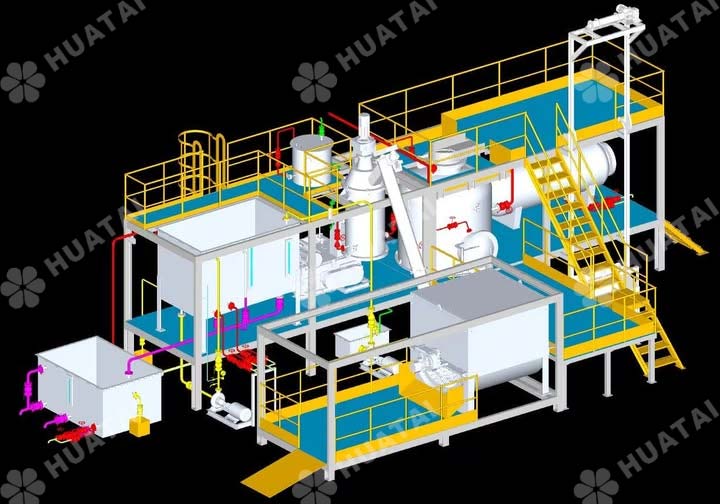

As one of the leading grain and oil machinery manufacturer, Henan Huatai Cereals and Oils Machinery Co., Ltd. focuses on the research and development and production of soybean oil processing equipment, providing a full set of solutions for pretreatment, pressing, extraction and refining. Its equipment has the following advantages:

1) High efficiency and energy saving: using advanced extraction and refining technology to improve oil yield and reduce energy consumption.

2) Automatic control: PLC intelligent control system to ensure stable soybean oil production and reduce manual intervention.

3) Compliance with international standards: The soybean oil equipment complies with ISO, CE and other certifications to meet domestic and foreign market needs.

3. Why Choose Huatai Oil Machinery?

1) 37+ years of industry experience, serving global customers, mature and reliable technology.

2) Customized solutions can provide soybean oil production lines of different sizes according to customer needs.

3) Perfect after-sales service, providing installation and commissioning, technical training and other support.

4. Conclusion

Soybean oil processing is a complex and delicate process, and it is crucial to choose high-quality soybean oil processing equipment. Henan Huatai Cereals and Oils Machinery Co., Ltd. relies on advanced technology and rich experience to provide customers with efficient and energy-saving soybean oil processing machine to help the high-quality development of the oil industry. If you need soybean oil processing equipment or technical consultation, please contact us, we will provide you with professional services!

Website: https://www.oilpresscn.com/

Email: info06@cnoilmachine.com