Huatai Oil Machinery is an entity manufacturer of cereals and oils machinery integrating R&D, manufacturing and after-sales. We are able to undertake peanut oil production line with 10-5000TPD Capacity to meet different customers' demands.

Huatai peanut oil production line is specially designed for peanut oil production, and controls the whole process from peanut pretreatment to finished product filling. It adopts low-temperature slow pressing technology to retain the natural fragrance and nutrition of peanuts and avoid high temperature damage. The original multi-stage filtration technology ensures that the oil is pure and free of impurities, and the color is golden and translucent.

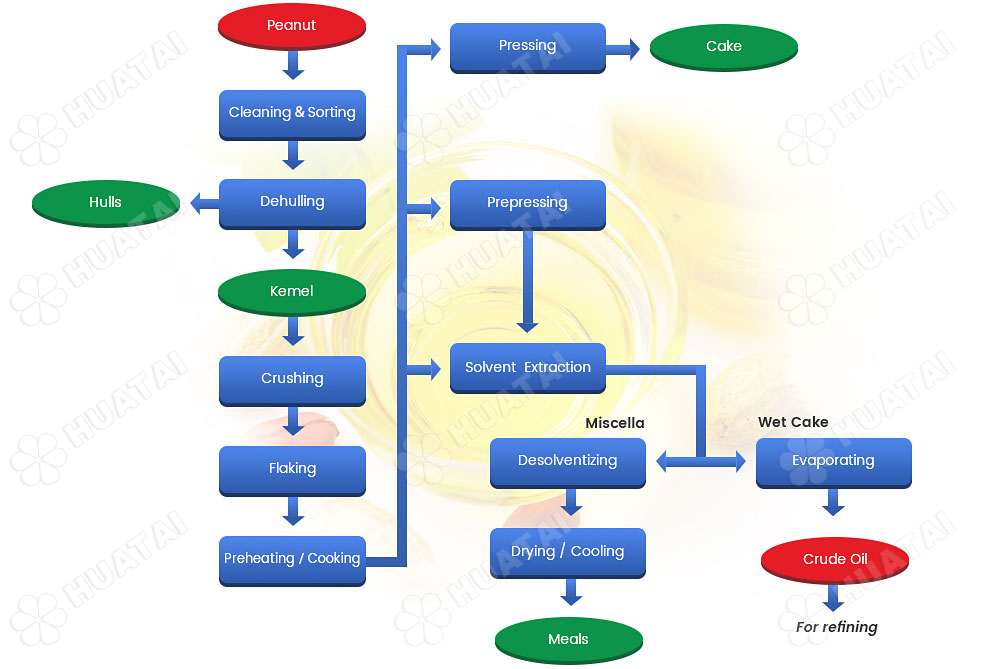

Peanut also called groundnut, is one kind of oilseed with high oil content and high nutritive value. The peanut kernel has 40%-51% oil content, which is also one of the most widely used oilseeds. Because of the high oil content, two types of the processing technology can both used in peanut oil making machine: pressing method and solvent extraction method. Which method used depends on your requirement and the capacity you want.

The peanut oil production line includes peanut oil pretreatment machine, peanut oil solvent extraction plant and peanut oil refinery plant.

1. Peanut Oil Pretreatment Plant:

1. Peanut Oil Pretreatment Plant:

Peanut→cleaning→stones removal→magnetic selection→crushing→softening→flaking→drying→to solvent extraction

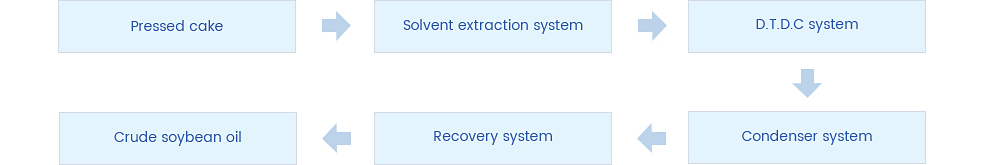

2. Peanut Oil Solvent Extraction Plant:

2. Peanut Oil Solvent Extraction Plant:

The peanut oil solvent extraction plant is part of peanut oil production line which is designed to extract oil directly from pressed peanut cake. After peanut oil solvent extraction plant, the residual oil rate in peanut cake is less than 1%.

Pressed cake→Solvent extraction system→D.T.D.C system→Condenser system→Recovery system→Crude peanut oil

3. Peanut Oil Refinery Plant:

3. Peanut Oil Refinery Plant:

After peanut oil solvent extraction process, there are some impurities in crude peanut oil. To get the higher quality final product oil, the crude peanut oil should be refined by oil refinery plant. Peanut oil refinery plant includes a series processing process such as degumming, neutralization, bleaching, deodorization and so on. In general there are two methods of peanut oil refining process, one is physical refining and the other is chemical refining. However, no matter what kinds of peanut oil refining methods, they are all done with the help of various oil processing equipment and machinery.

Crude peanut oil-degumming--deacidifaction--decolorization--deodorization--refined peanutoil.

And there are three types of the refinery equipment: batch type, semi-continuous type and full-continuous type.

4. Application of Groundnut Oil Refinery Plant:

4. Application of Groundnut Oil Refinery Plant:

After refining, we can get refined, bleached, deodorized oil. That is, first-grade peanut oil. Peanut oil refinery plant are also used to refine almost kinds of oil extracted from oil seeds like sunflower seeds, peanuts, sesame seeds, and soybean seeds etc.

5. Company Strength and Advantages

5. Company Strength and Advantages

Henan Huatai Cereals and Oils Machinery Co., Ltd. was established in 1988. It is a national high-tech enterprise with many patented technologies in the field of groundnut oil processing. The company's production base covers an area of 100,000 square meters and is equipped with large CNC machining centers, automated welding equipment and testing laboratories. The company has established a complete after-sales service system, with multiple agency centers and service outlets in major markets around the world, providing free technical consultation, and has been exported to Southeast Asia, Africa, South America and other regions.

As one of the top grain and oil machinery manufacturer and supplier, with many provincial honors and the experience in building hundreds of peanut oil mills, Henan Huatai Cereals and Oils Machinery Co., Ltd. has outstanding strength in the field of peanut oil production line, focusing on peanut oil technology innovation and process improvement for many years.

With rich industry experience, we provide customers with a full range of solutions from peanut cleaning processing to peanut oil refining and packaging. For different peanut oil production processes, we can provide customized 10-5000TPD peanut oil production lines, support a variety of capacity tonnage and process combinations, to meet the diverse needs of customers.

6. After-sales and Maintenance Services

6. After-sales and Maintenance Services

Henan Huatai Cereals and Oils Machinery Co., Ltd., as one of the professional oil and fat equipment manufacturer, usually provides after-sales and maintenance services for peanut oil processing equipment in the following aspects (subject to the company's latest policy):

Equipment installation and commissioning

Equipment installation and commissioning

1) On-site guidance: Send engineers to the customer's peanut oil factory to provide guidance on the installation of peanut oil equipment to ensure that the equipment is properly in place.

2) Commissioning service: Assist in completing peanut oil equipment no-load and load commissioning and optimize peanut oil production process parameters.

3) Operation training: Provide equipment operation, maintenance and safety specification training for customer technicians.

Warranty and maintenance

Warranty and maintenance

1) Warranty period: Provide a warranty period of 1-3 years (depending on the terms of the contract), and handle problems caused by equipment quality free of charge during the warranty period.

2) Fault response: Set up a 48-hour service hotline to quickly respond to fault reports and quickly send engineers to the site for inspection and repair when necessary.

3) Accessories supply: Provide original accessories at a preferential price to ensure long-term and stable operation of the peanut oil machine.

Technical support and upgrade

Technical support and upgrade

1) Process optimization: Adjust equipment parameters according to customer needs to improve oil yield and energy efficiency.

2) Technical consultation: Provide free technical consultation for life to answer difficult problems in production.

3) Equipment upgrade: Provide peanut oil plant upgrade and technology iteration solutions (such as control system upgrade, energy-saving transformation, etc.).

How to Set Up a Peanut Oil Processing Plant?

How to Set Up a Peanut Oil Processing Plant?

To build a peanut oil production line, many aspects need to be considered.

Huatai Oil Machinery has extensive experience in building turnkey project peanutoil production line and overseas export of peanut oil processing equipment. To buy our peanut oil equipment, just provide the following information and we will arrange an experienced foreign trade sales manager to talk with you:

Peanut oil equipment parameters and list:

1) What capacity of peanut oil production machine do you need? How many tons do you deal with peanut every day? Or how much crude peanut oil do you want?

2) Do you just process peanut fruit/kernel or multiple oilseeds? Do you need a single equipment, an entire workshop, or the complete set of peanut oil turnkey projects?

3) What peanut oil process do you need? Pressing, solvent extraction, refining equipment or others?

4) Do you have a certain amount of budget and land that meets the conditions for building a peanut oil factory?

5) Other export trade needs, such as contract signing details, payment methods, logistics and installation and construction, etc.

Please leave us a message as detailed inquiry information as possible, so that we can provide you with equipment quotation, process flow, equipment configuration list and other services, thank you.