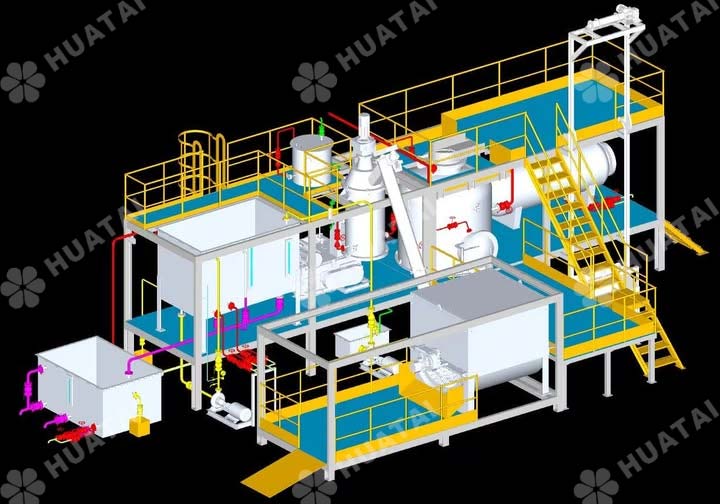

Low-temperature cold filtration technology is one of the processes used in edible oil production to remove impurities and improve the quality of edible oil. This process is mainly used in the edible oil refining process. It is filtered and cooled by a centrifugal filter after hydration refining to ensure that the oil is clear and transparent and of high quality.

The low-temperature cold filtration process can retain the nutrients and aroma of edible oil, remove impurities by low-temperature filtration, and maintain the purity and rich aroma of the oil. It is very common in the production of fragrant peanut oil. The cold filtration process has the following advantages in fragrant peanut oil processing:

1. Low oil loss

In the traditional edible oil refining process, on the one hand, the hydration degumming process is used to remove the phospholipid content in the oil. In this process, due to the emulsification of some neutral oils with water, the oil loss is relatively high, generally 0.5 times the phospholipid content, about 0.5% of the total mass of crude oil. On the other hand, in the alkali refining and deacidification process, some neutral oils and alkalis generate soaps and become soap stock to be discharged, and the loss is about 0.5%. Therefore, the refining consumption of chemical refining is generally 1.0%. In contrast, the low-temperature refining process adopts a pure physical filtration process, which basically has no oil loss, and the loss in the refining process is greatly reduced.

2. Green oil and no chemical pollution

The traditional peanut oil refining process is a chemical refining process. The main processes include hydration degumming, alkali refining and deacidification, clay decolorization, vacuum dehydration, deodorization, filtration, etc. The traditional refining method has a great damage to the inherent components in peanut oil, high refining consumption, and a small amount of chemical pollutants will remain.

The low-temperature filtration process of peanut oil is different from the traditional refining process. It is a low-temperature refining process that does not consume steam and has no chemical pollution. The product is green and healthy, and the nutrients, physiologically active ingredients and unique flavors in peanuts are better preserved, and the oil can be kept clear and transparent for a long time.

3. Good oil nutrition retention

The low-temperature filtration process of peanut oil can fully retain the nutrients, physiologically active ingredients and unique flavors in peanuts, and can keep the oil clear and transparent for a long time. The technology is simple, the process is reliable, the investment is small, and the benefits are significant. This process has been successfully applied in practice with significant benefits.

Peanut oil low temperature filtration process have low energy consumption, small refining consumption, no steam consumption, high resource utilization rate, and no waste discharge. It is an environmentally friendly new process that meets the current requirements of "energy conservation and emission reduction" and the construction of a circular economy proposed, and also saves equipment investment costs and production costs for edible oil mills. Henan Huatai Cereals and Oils Machinery Co., Ltd. provides customers with a full set of peanut oil processing equipment and processing technology, free technical process services, equipment installation and commissioning, employee training, and perfect after-sales service. If you have any equipment needs, welcome to contact us.

Website: https://www.oilpresscn.com/

Email: info06@cnoilmachine.com