Palm oil is the world's second largest edible vegetable oil. Palm oil refinery plays an important role in palm oil production line. Huatai palm oil refinery plant adopts advanced technology and is designed for efficient purification of palm oil, covering the whole process of degumming, deacidification, decolorization, deodorization, etc.

The palm oil refining machine has the characteristics of high degree of automation, low energy consumption, stable quality of finished palm oil, etc. It can be customized 2-600TPD Capacity and meet the processing needs of different scales and meet the international food safety standards. Huatai palm oil refining plant is an ideal choice for improving the efficiency and economic benefits of palm oil refining.

In the palm oil processing plant, palm oil refining machine can be divided into intermittent palm oil refining machine, semi-continuous palm oil refining machine and fully continuous palm oil refining machine.

According to palm oil refining process, palm oil refining machine can be divided into palm oil chemical refining machine and palm oil physical refining machine.

According to palm oil refining processing capacity, palm oil refining machine can be divided into small 2-10 tons/day palm oil refining machine, medium-sized 20-50 tons/day palm oil refining machine, large-scale palm oil refining machine with a capacity of more than 100 tons/day.

According to material, there are general carbon steel plus stainless steel palm oil refining machine and all-stainless steel palm oil refining machine.

The purpose of palm oil refining machine in palm oil mill plant is to remove impurities, to achieve the finished product oil standard.

The Main Process of Palm Oil Refining Machine:

The Main Process of Palm Oil Refining Machine:

Crude palm oil ➞ degumming ➞ neutralization ➞ decoloration ➞deodorization➞ fractionation

Crude oil filter: Buy back crude oil should be filtered suspended particles impurities and other impurities to the following production.

Crude oil filter: Buy back crude oil should be filtered suspended particles impurities and other impurities to the following production.

Degumming: Pump crude palm oil in, stir quickly, and use direct steam or thermal oil to heat in a coil heater. It is necessary to control the amount of water added, the water temperature and the speed of adding water. During this period, the peptidic impurities will slowly turn into floc. Batch and semi-continuous palm oil refining machine use precipitation separation, while fully continuous palm oil refining machine requires a centrifugal separator.

Degumming: Pump crude palm oil in, stir quickly, and use direct steam or thermal oil to heat in a coil heater. It is necessary to control the amount of water added, the water temperature and the speed of adding water. During this period, the peptidic impurities will slowly turn into floc. Batch and semi-continuous palm oil refining machine use precipitation separation, while fully continuous palm oil refining machine requires a centrifugal separator.

Deacidification: Add alkali to neutralize free fatty acids. Intermittent palm oil refining machine still uses the precipitation separation method, while semi-continuous refining and fully continuous palm oil refining equipment use the distillation method together with deodorization.

Deacidification: Add alkali to neutralize free fatty acids. Intermittent palm oil refining machine still uses the precipitation separation method, while semi-continuous refining and fully continuous palm oil refining equipment use the distillation method together with deodorization.

Decolorization: Vacuum inhale a certain amount of decolorizing agent (activated clay/activated carbon), continue stirring and heating for 25 minutes, and then pump the mixture into the filter to separate the oil and decolorizing agent.

Decolorization: Vacuum inhale a certain amount of decolorizing agent (activated clay/activated carbon), continue stirring and heating for 25 minutes, and then pump the mixture into the filter to separate the oil and decolorizing agent.

Deodorization: Pump in the decolorized oil and heat it. When the oil temperature reaches above 100℃, direct steam is introduced to take away the odorous substances.

Deodorization: Pump in the decolorized oil and heat it. When the oil temperature reaches above 100℃, direct steam is introduced to take away the odorous substances.

The Main Components of Palm Oil Refining Machine:

The Main Components of Palm Oil Refining Machine:

Neutralization pot: It is mainly used for acid refining, alkali refining or water washing of oil in oil refining equipment; (consumables, phosphoric acid or alkali, hot water)

Neutralization pot: It is mainly used for acid refining, alkali refining or water washing of oil in oil refining equipment; (consumables, phosphoric acid or alkali, hot water)

Decolorization pot: It needs to be filtered and bleached with white clay to remove colored impurities and pigments in oil;

Decolorization pot: It needs to be filtered and bleached with white clay to remove colored impurities and pigments in oil;

Deodorization pot: It is used to remove the odor of oil in oil refining equipment (made of stainless steel, with vacuum inside);

Deodorization pot: It is used to remove the odor of oil in oil refining equipment (made of stainless steel, with vacuum inside);

Thermal oil furnace: It provides the heat energy required for production of oil refining equipment, and the temperature reaches 280℃;

Thermal oil furnace: It provides the heat energy required for production of oil refining equipment, and the temperature reaches 280℃;

Vacuum pump: It provides the vacuum required for decolorization and deodorization, which can reach more than 755mmHg;

Vacuum pump: It provides the vacuum required for decolorization and deodorization, which can reach more than 755mmHg;

Air compressor: It blows dry the decolorization white clay;

Air compressor: It blows dry the decolorization white clay;

Filter press: It filters the white clay;

Filter press: It filters the white clay;

Steam generator: It generates steam required for deodorization distillation.

Steam generator: It generates steam required for deodorization distillation.

The crude oil by the palm oil press machine is refined by alkali, washed, decolorized and deodorized, and then it becomes the finished secondary salad oil, which can be filled after cooling.

Process Characteristics of Complete Palm Oil Refinery Turnkey Project:

Process Characteristics of Complete Palm Oil Refinery Turnkey Project:

Continuous alkali refining shortens the contact time between oil and alkali solution, reduces oil saponification, reduces refining consumption, and improves yield.

Continuous alkali refining shortens the contact time between oil and alkali solution, reduces oil saponification, reduces refining consumption, and improves yield.

Palm oil decolorization adopts a process combining premixing and steam stirring decolorization to improve decolorization efficiency, save white clay, simple and convenient operation, and negative pressure state prevents oxygen in the air from contacting hot oil, ensuring oil quality, inhibiting acid value recovery, and reducing peroxide value.

Palm oil decolorization adopts a process combining premixing and steam stirring decolorization to improve decolorization efficiency, save white clay, simple and convenient operation, and negative pressure state prevents oxygen in the air from contacting hot oil, ensuring oil quality, inhibiting acid value recovery, and reducing peroxide value.

Palm oil deodorization process uses a new type of continuous deodorization equipment, which is suitable for the deacidification and deodorization of vegetable oils with high acid value and low colloid content. Actual production has proved its obvious advantages: strong deacidification ability, good thermal decolorization effect, high refining rate, steam saving, good oil quality, etc.

Palm oil deodorization process uses a new type of continuous deodorization equipment, which is suitable for the deacidification and deodorization of vegetable oils with high acid value and low colloid content. Actual production has proved its obvious advantages: strong deacidification ability, good thermal decolorization effect, high refining rate, steam saving, good oil quality, etc.

The palm oil refining process performs multiple heat exchanges, fully utilizes the system heat energy, effectively reduces steam consumption, and has the advantages of adjustable production process, flexible operation, high degree of automation, and good environmental hygiene.

The palm oil refining process performs multiple heat exchanges, fully utilizes the system heat energy, effectively reduces steam consumption, and has the advantages of adjustable production process, flexible operation, high degree of automation, and good environmental hygiene.

Company Strength and Advantages

Company Strength and Advantages

Henan Huatai Cereals and Oils Machinery Co., Ltd. was established in 1988. It is a national high-tech enterprise with many patented technologies in the field of palm oil refining processing. The company's production base covers an area of 100,000 square meters and is equipped with large CNC machining centers, automated welding equipment and testing laboratories. The company has established a complete after-sales service system, with multiple agency centers and service outlets in major markets around the world, providing free technical consultation, and has been exported to Southeast Asia, Africa, South America and other regions.

With its strong technical strength, Huatai Oil Machinery has obtained many patents in the field of palm oil refining and fractionation machine. The palm oil refining equipment we produced has won the first prize of edible oil refining technology of the China Grain and Oil Society for many times, and has accumulated a good market reputation and honor in the field of palm oil refining and fractionation process. Relying on China's leading modern oil equipment industry R&D and production base, we provide customers with cutting-edge and reliable palm oil refining and fractionation plant.

According to different capacity tonnage and production process requirements, we can carry out the refined customization to meet the different equipment requirements of small, medium and large-scale palm oil processing plants, and ensure the efficiency and stability of the palm oil refining and fractionation process.

After-sales and Maintenance Services

After-sales and Maintenance Services

Henan Huatai Cereals and Oils Machinery Co., Ltd., as one of the professional oil and fat equipment manufacturer, usually provides after-sales and maintenance services for palm oil processing equipment in the following aspects (subject to the company's latest policy):

Equipment installation and commissioning

Equipment installation and commissioning

1) On-site guidance: Send engineers to the customer's palm oil factory to provide guidance on the installation of palm oil equipment to ensure that the equipment is properly in place.

2) Commissioning service: Assist in completing palm oil equipment no-load and load commissioning and optimize palm oil production process parameters.

3) Operation training: Provide equipment operation, maintenance and safety specification training for customer technicians.

Warranty and maintenance

Warranty and maintenance

1) Warranty period: Provide a warranty period of 1-3 years (depending on the terms of the contract), and handle problems caused by equipment quality free of charge during the warranty period.

2) Fault response: Set up a 48-hour service hotline to quickly respond to fault reports and quickly send engineers to the site for inspection and repair when necessary.

3) Accessories supply: Provide original accessories at a preferential price to ensure long-term and stable operation of the palm oil machine.

Technical support and upgrade

Technical support and upgrade

1) Process optimization: Adjust equipment parameters according to customer needs to improve oil yield and energy efficiency.

2) Technical consultation: Provide free technical consultation for life to answer difficult problems in production.

3) Equipment upgrade: Provide palm oil plant upgrade and technology iteration solutions (such as control system upgrade, energy-saving transformation, etc.).

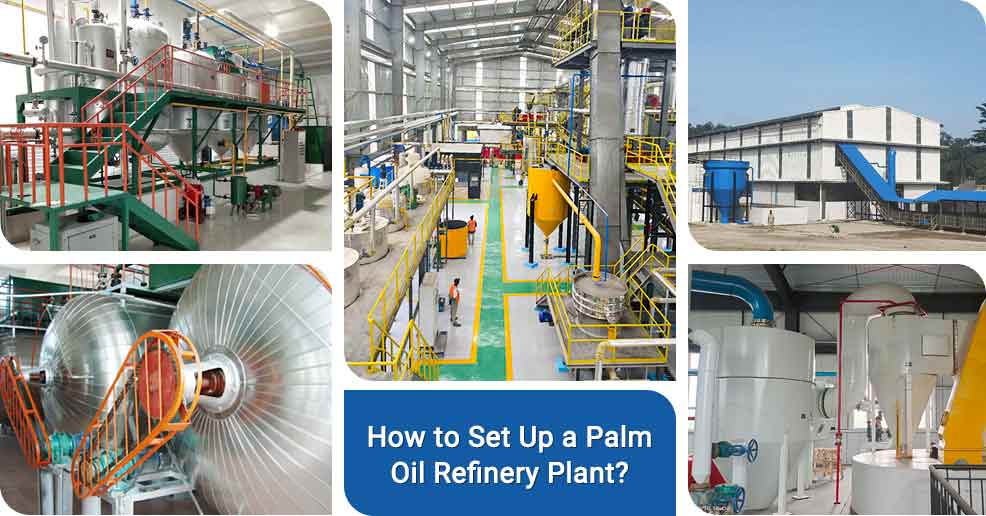

How to Set Up a Palm Oil Refinery Plant?

How to Set Up a Palm Oil Refinery Plant?

To build a palm oil refining line, many aspects need to be considered.

Huatai Oil Machinery has extensive experience in building turnkey project palm oil refinery and overseas export of palm oil refining equipment. To buy our palm oil equipment, just provide the following information and we will arrange an experienced foreign trade sales manager to talk with you:

Palm oil equipment parameters and list:

1) What capacity of palm oil refining machine do you need? How many tons do you deal with crude palm oil (CPO) every day? Or how many tons of refined palm oil (RBD palm oil) do you want?

2) Do you just process crude palm oil or multiple oilseeds? Do you need a single equipment, an entire workshop, or the complete set of palm oil turnkey projects?

3) What palm oil process do you need? Pressing, solvent extraction, refining equipment, fractiontion or others?

4) Do you have a certain amount of budget and land that meets the conditions for building a palm oil refinery?

5) Other export trade needs, such as contract signing details, payment methods, logistics and installation and construction, etc.

Please leave us a message as detailed inquiry information as possible, so that we can provide you with equipment quotation, process flow, equipment configuration list and other services, thank you.