The process of making groundnut oil involves several steps:

Cleaning: After harvesting, groundnuts are received at processing facilities. The peanuts are then cleaned using a cleaning machine to remove foreign materials such as leaves, nodes, weed seeds, etc.

Dehulling: After cleaning, the outer shell is removed as it does not contain oil. This can be done manually or by using a dehuller.

Cooking: This step assists in breaking the cell walls and opens the cells that contain the oil. It also decreases the thickness of the oil so that it flows out more easily.

Pressing: The peanuts are transferred by conveyor and fed through the hopper of a peanut oil screw press machine. Continuous transport of material by the screw shaft causes pressure to increase to a level needed, which increases friction inside the screw press and generates heat which lowers viscosity of the oil in the crushed seeds thereby increasing the oil flow rate.

Filtration: After pressing, crude peanut oil still contains impurities. To aid in the removal of these remaining impurities, oil filter press machines are usually employed.

These steps ensure that the groundnut oil produced is pure and ready for use.

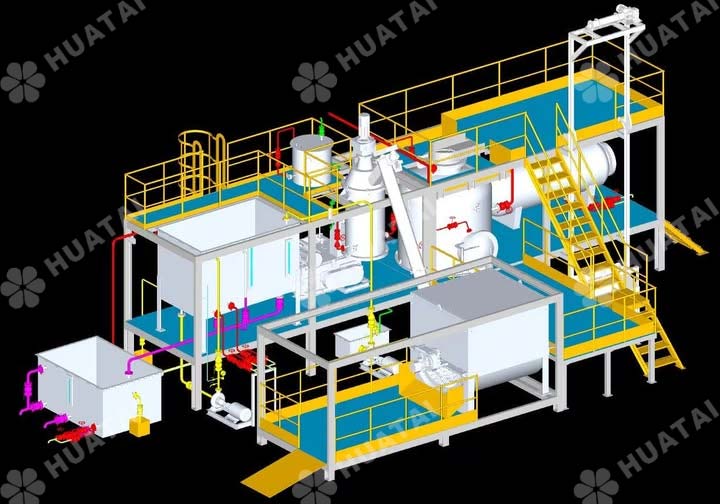

To consult and purchase groundnut oil production machine, you can go to Henan Huatai Cereals and Oils Machinery Co., Ltd. Huatai Oil Machinery specializes in the production of oil equipment, mainly cooking oil press machine, vegetable oil refining equipment, edible oil extraction machine, complete edible oil production lines, etc. From raw material pretreatment to finished oil filling, the equipment models are complete and the quality is good. The manufacturer can purchase all in one stop. Huatai Oil Machinery provides customized services for edible oil plants, from cooking oil plant design, production, installation, operation and other services, free operation training, to provide guarantees for the smooth production of the edible oil plant. Welcome to visit the factory.

Website: https://www.oilpresscn.com/

Email: info06@cnoilmachine.com