Peanuts are not only nutritious but also an excellent raw material for pressing high-quality edible oil. Behind a bottle of pure, clear, and fragrant peanut oil lies a rigorous and scientific processing technique. As a leading grain and oil machinery manufacturer, Henan Huatai Cereals and Oils Machinery Co., Ltd. will demystify peanut oil production step by step, providing a detailed explanation of the complete production process from peanuts to edible oil, including the core techniques and specialized equipment required, to help you gain a deeper understanding of this industry that blends tradition with modern technology.

Step 1: Pretreatment of Peanut Raw Materials

Producing high-quality groundnut oil requires high-quality raw materials and precise pretreatment.

1) Cleaning and Screening: Purchased peanut kernels are often contaminated with impurities such as stones, dirt, and stems and leaves. Huatai's cleaning screens and de-stoners are essential to efficiently remove impurities, ensure raw material purity, and prevent damage to subsequent groundnut oil equipment.

2) Shelling and Separation: Peanut shells have a very low oil content, which can affect oil yield and oil quality. Peanut shellers separate the kernels from the shells, and an air separation system thoroughly separates the kernels from the shells. This step significantly improves oil extraction efficiency and quality.

3) Crushing and Flaking: The pure peanut kernels are crushed into medium-sized particles in a crusher and then pressed into thin, raw embryos using a flaking machine. Flaking disrupts the peanut's cellular structure, increasing its surface area for subsequent steaming, stir-frying, and oil extraction.

Step 2: Groundnut Oil Extraction Process

This is the key step in extracting the oil from the peanuts. There are two main methods:

1) Pressing:

Hot Pressing: The flaked peanut embryos are steamed and stir-fried in a Huatai wok to develop their unique aroma. They are then physically pressed in a screw press. This method produces a rich and fragrant oil, but the residual oil content in the kernel is slightly higher. Huatai's high-efficiency screw presses are renowned for their high oil yield and stable operation.

Cold Pressing: The steaming and stir-frying steps are omitted, and the peanuts are directly pressed at low temperatures using an oil press. This method better preserves the natural nutrients and flavor of peanuts, but results in a lower oil yield and a weaker oil aroma.

2) Groundnut Oil Extraction Method:

This is a large-scale, highly efficient oil production method. First, a pre-press is used to remove a portion of the oil, resulting in a pre-pressed cake. The cake is then fed into a Huatai edible oil extractor, where it is soaked in a food-grade solvent (such as n-hexane) to dissolve almost all of the remaining oil. This method offers an extremely high oil yield, with the residual oil content in the cake below 1%.

Step 3: Crude Groundnut Oil Refining

Whether obtained by pressing or extraction, it is called "crude oil." It contains phospholipids, free fatty acids, pigments, and odor-causing substances, and must be refined to become a safe, clear, and nationally compliant edible oil. Huatai Oil Machinery offers a complete peanut oil refining equipment, including:

1) Degumming: Phospholipids and gum are removed from the crude oil through hydration.

2) Deacidification: Free fatty acids are neutralized and removed through alkali refining.

3) Decolorization: Huatai decolorization towers and activated clay are used to remove pigments through adsorption, resulting in a clear, bright oil.

4) Deodorization: High vacuum and steam distillation are used in high-temperature deodorization towers to remove odorous substances and volatile components from the oil and kill microorganisms. This is a critical step in determining the oil's flavor and stability.

5) Bottling: The refined peanut oil, with its translucent color, pure flavor, and long shelf life, is ready for bottled and sold.

Why Choose Henan Huatai Cereals and Oils Machinery Co., Ltd.?

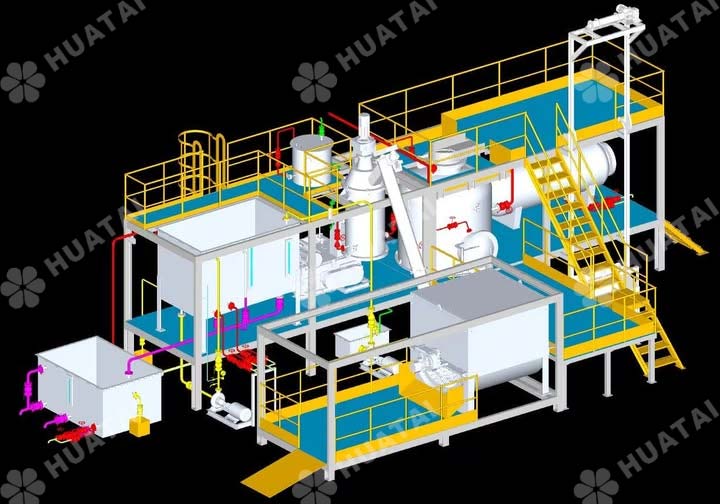

If you are planning to invest in a peanut oil processing plant, Henan Huatai Cereals and Oils Machinery Co., Ltd. is your trusted partner.

1) Extensive Experience: With years of experience in the grain and oil machinery industry, we have a deep understanding of peanut oil processing technology.

2) Complete Equipment: Huatai provides a complete turnkey project from pretreatment, pressing/extraction, to refining, featuring reliable equipment and advanced technology.

3) Leading Technology: Huatai can customize optimized groundnut oil production line solutions based on customer needs, ensuring both oil yield and quality.

Conclusion

From an ordinary peanut to a bottle of high-quality edible oil, every step requires rigorous craftsmanship and reliable machinery. Henan Huatai Cereals and Oils Machinery Co., Ltd. is an expert and enabler in this process. Whether you're a small cooking oil mill or a large edible oil processing company, Huatai can provide you with the most professional peanut oil production solutions.

Website: https://www.oilpresscn.com/

Email: info06@cnoilmachine.com